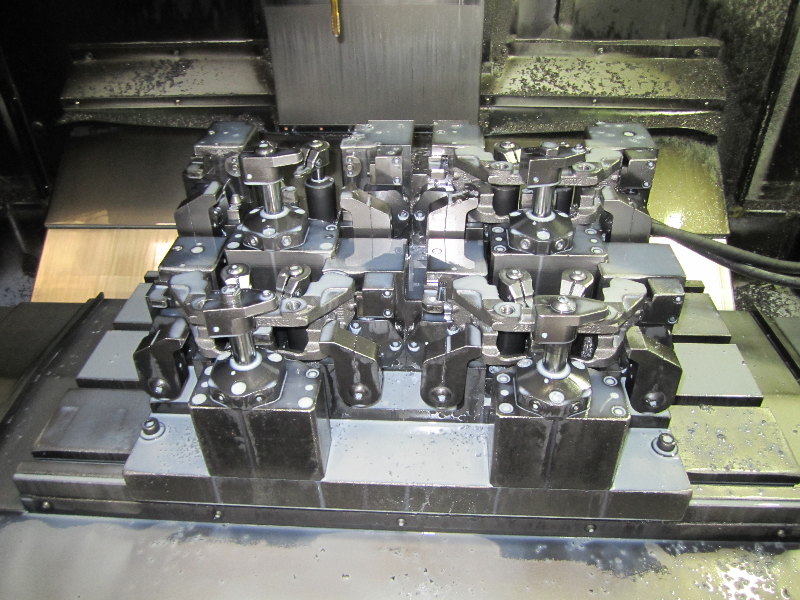

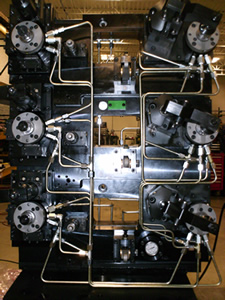

Turn-Key Solutions is an industry leading in providing custom workholding fixtures. Our extensive background in metal removal allows TKS to design and manufacture the best fixturing solutions available.

Turn-Key Solutions is an industry leading in providing custom workholding fixtures. Our extensive background in metal removal allows TKS to design and manufacture the best fixturing solutions available.

Our in-house engineering staff utilizes the latest CAD/CAM and FEA software to securely and reliably grip your component without distortion. Our company philosophy is to keep engineering, manufacturing, assembly and testing in-house to ensure that your fixturing will exceed your expectations at an affordable price.

TKS can also offer value added options like tooling selection, CNC programming, installation, PAPP or a complete turnkey on our floor with your CNC.

Turn-Key Solutions workholding solutions include:

Turn-Key Solutions workholding solutions include:

- Custom live hydraulic workholding fixtures

- Custom closed circuit workholding fixtures

- Custom trunnion workholding fixtures

- Custom manual clamping fixtures

- CMM verification of datum points/location elements

- Verification of customer supplied tooling package to ensure a seamless installation

- CNC programming (VMC, HMC or lathe)

- Installation on your floor with a TKS supplied tooling package or your tooling

- PPAP on your floor with a 1.67 or 2.0 CPK

- Complete Turn-Key Solution that includes fixture design, manufacture, build, part processing, tooling selection, CNC programming and a runoff on your floor