Our Services

High-volume manufacturing Solutions

The TKS team has years of experience building specialized high-volume machines for drilling, milling, grinding, leak test and turning applications. Our dedicated machines are capable of achieving high production rates without sacrificing part quality. By coupling an optimized machining process with automated part handling and in-process gauging, TKS can provide your company with a comprehensive highvolume machining solution.

Leak Test Solutions

TKS leak test machines are designed to produce test results that verify a products performance by simulating real world conditions defined by our customers specifications.

Machine Rebuild and Retrofit Solutions

Many companies own older equipment that is not fulfilling their current needs . Often, due to its condition, this equipment is unable to meet the required overall equipment effectiveness (OEE) or experiences excessive downtime due to obsolete controls. Our experienced technicians will assess your current equipment and replace damaged or worn components, returning your existing equipment to the manufacturers original specifications. Additionally, outdated controls and electronics can be updated to current industry standards. Our machine rebuild and upgrade solutions are a cost effective method to extend the productive life of your equipment.

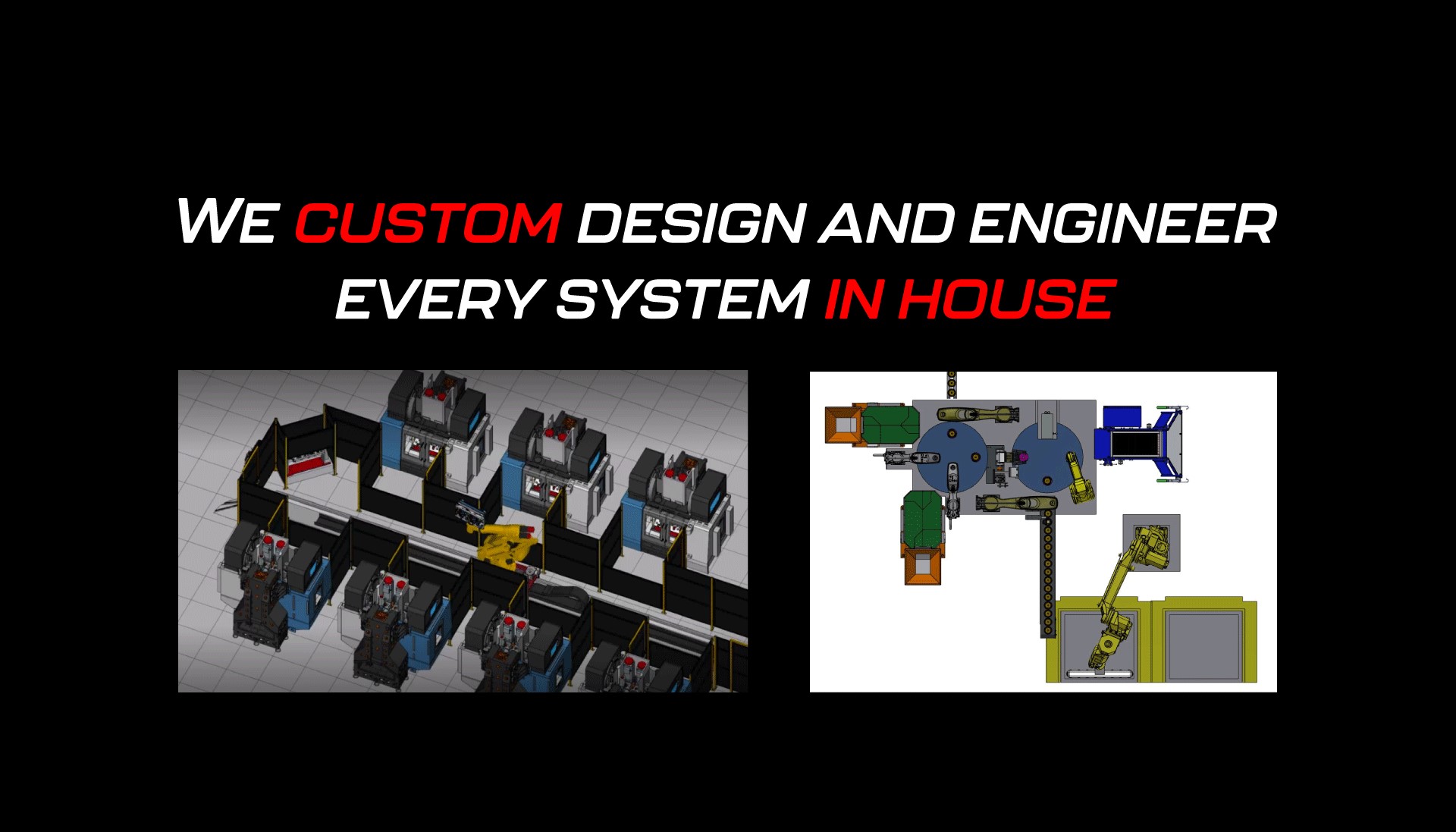

Robotic Automation Solutions

With in-depth understanding of the manufacturing environment and it’s equipment, TKS delivers tailored automation solutions that capitalize on the precision and time saving benefits of robotic integration. Repetitive, dangerous or ergonomically undesirable tasks can be eliminated with the addition of a single, or multiple robots, into a product cell, increasing productivity. With our precise and flexible robotic automation solutions, TKS can assist our customers in remaining competitive in their respective markets.

Fixturing Solutions

Drawing from an extensive background in metal removal, TKS designs and manufactures custom fixturing solutions. Utilizing the latest CAD/CAM and FEA software, our fixtures are engineered to

securely and reliably grip your component without distortion. Any custom components are manufactured in-house using precision CNC equipment. This allows us to provide you with a quality fixture at an affordable price.

Automated Assembly Solutions

TKS supplies “state of the art” assembly equipment by combining our part handling and machine building expertise with the integration of technologies such as force/distance monitoring, torque monitoring and vision. By reducing the amount of human interface necessary, our automated assembly solutions are able to efficiently produce consistent quality components at a competitive cost.

What our clients say

I would like to express our gratitude for your attention during the Factory Acceptance Test (FAT) event at your facility this week. We noticed that your team put forth a tremendous amount of effort into developing the system, and we were highly impressed with the outcome. The level of proficiency demonstrated during the event was indicative of the dedication and hard work that your team has put into this project. We appreciate your commitment to excellence and look forward to continued collaboration.

We have had the pleasure of working with TKS for 6 years now and have experienced all the traits required in a successful integrator. TKS is always willing to investigate project concepts no matter how outrageous the requests can be. If I had to pick one trait that separates TKS from others is how open and transparent they are across all fronts pertaining to a project, regardless of whether it’s a $10k or $10M project. Unfortunately that trait is not as common as it should be so it’s hard to describe just how much of a breath of fresh air it is to work with TKS. Keep up the great work!

We have worked with TKS on several projects and I have yet to find any major flaws. The only one I can think of is that they stay busy but that is normal for a good integrator. We have tasked TKS with project ranging from $10K to $1M and they provide the same customer care regardless of our investment. They WILL stand behind their work and provide customer support when needed. Again, they are a strong outfit which is why several of our Snap-on plants do business with them.

TKS is certainly one of the best I have worked with in the past 10 years. They are on time, reasonably priced, can provide expedited service, can provide prototypes, and they also offer on-site assistance (something that is hard to find these days). I would recommend using TKS for your fixturing and tooling needs.

Our Customers